Integrated Design & Development Solutions for

Manufacturing Industries

Integrated Design & Development Solutions for

Manufacturing Industries

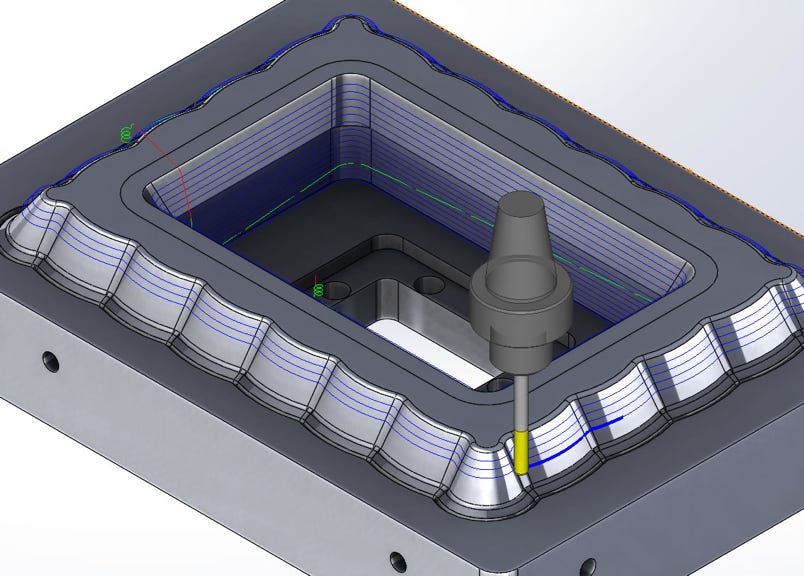

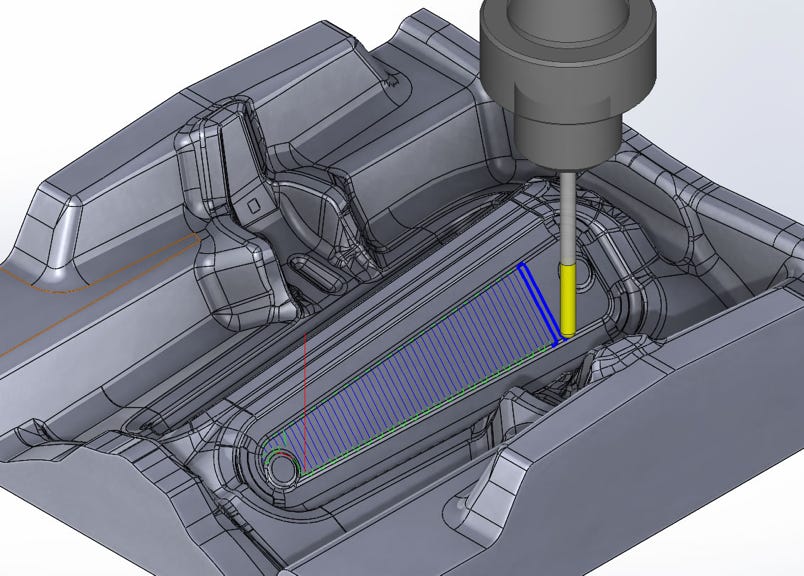

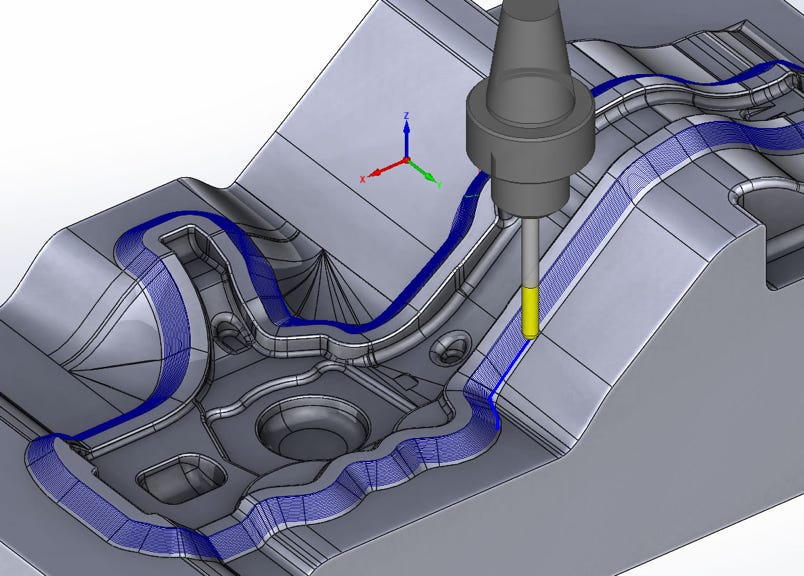

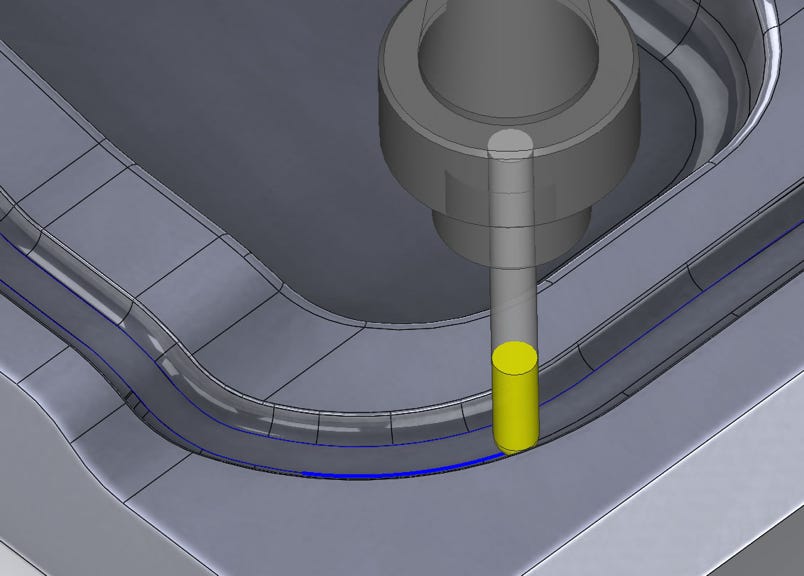

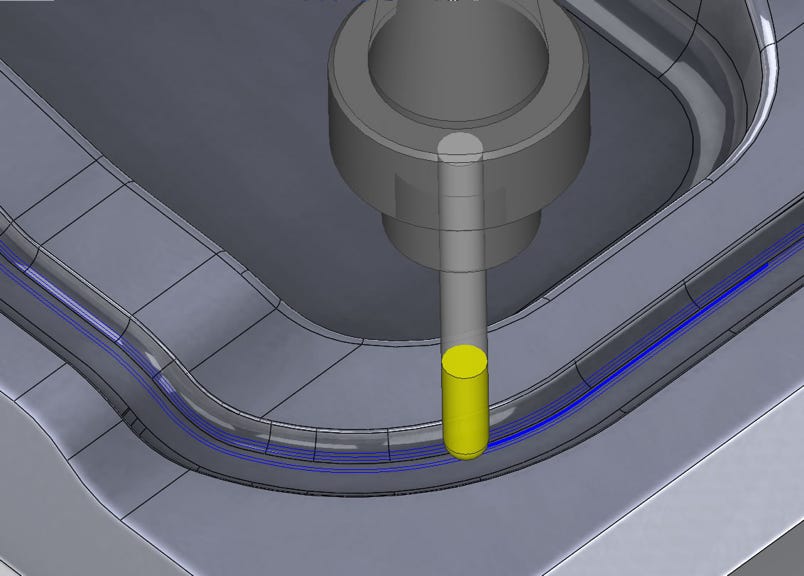

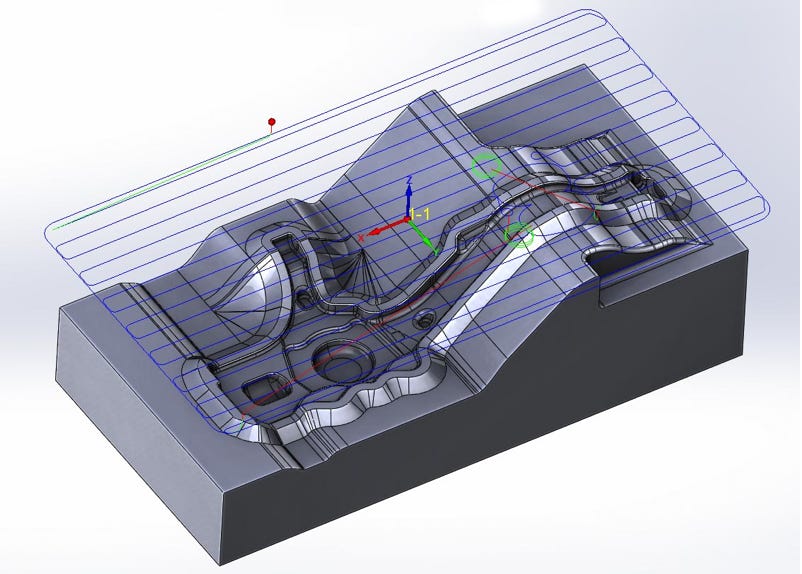

HSR Finishing

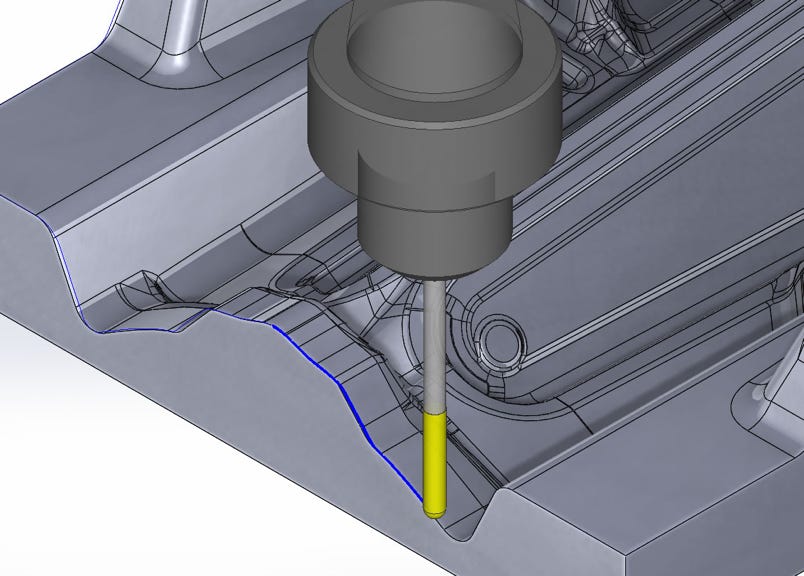

Constant-Z Machining

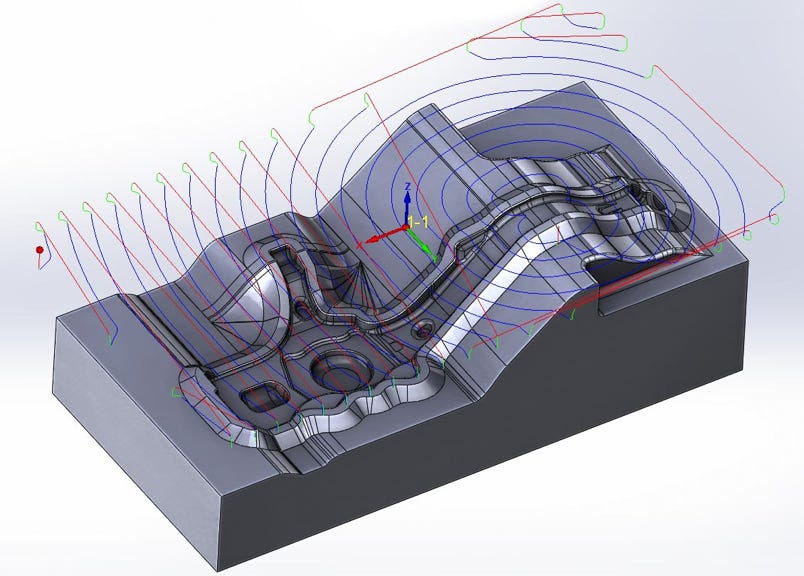

Hybrid Constant-Z

Helical Machining

Tool path follows asurface contour at different z-heights - best for semi-finishing and finishing of steep walls.

Combination of a traditional Constant Z strategy with 3D pocketing. Adding additional passes when there is a shallow area between consecutive passes, makes this strategy the best for the optimal finishing of the entire part

Covers the whole model with continuous descending helical tool paths, avoiding needless jumps to clearance area.

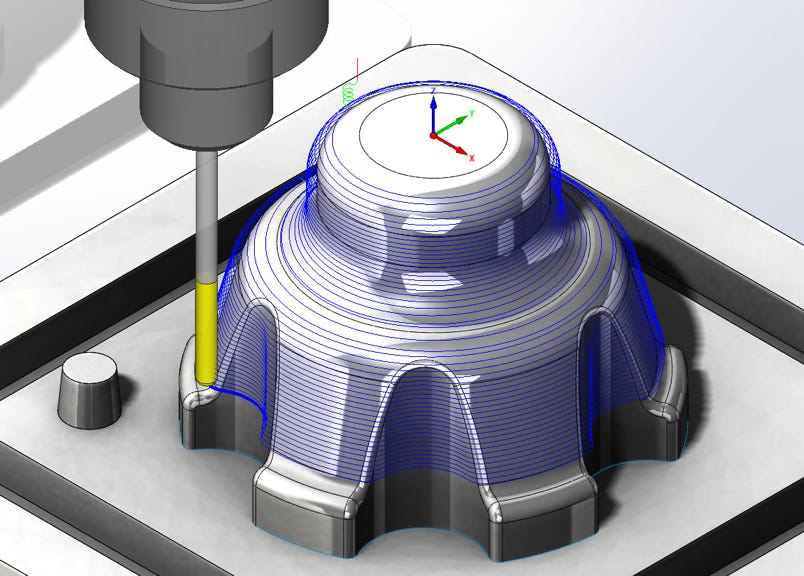

Horizontal Machining

Linear Machining

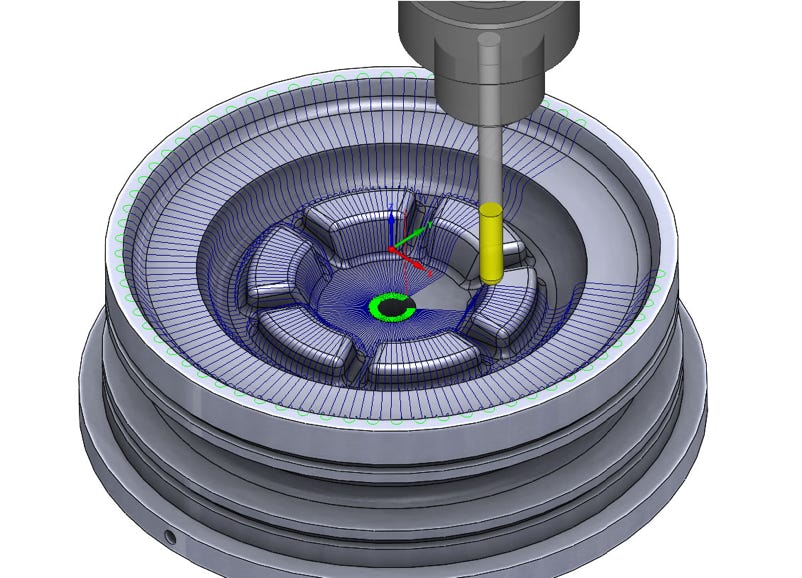

Radical Machining

Automatically detects all flat areas of the part and clears them with an offsetting path at the z-level of each area.

Creates tool paths from linear patterns generated by a defined Step Over projected onto a model surface.

Generates a Radial pattern around a defined central point projected onto a model surface

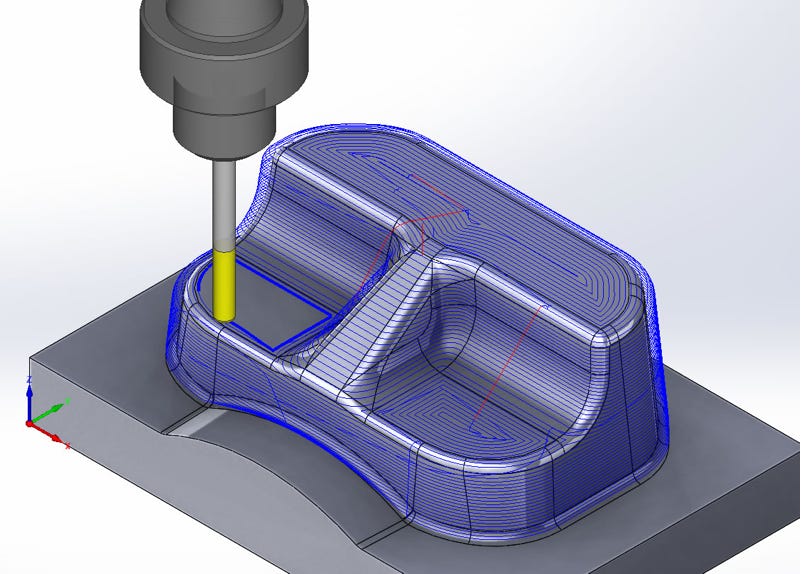

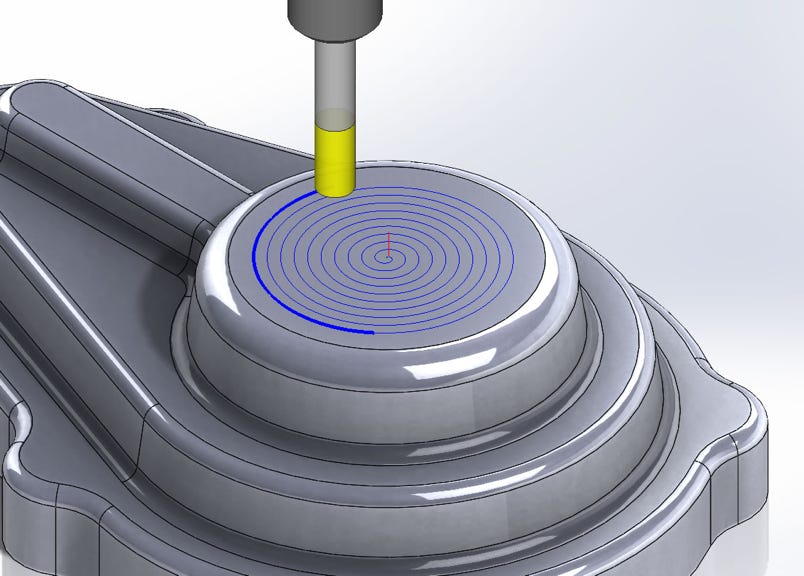

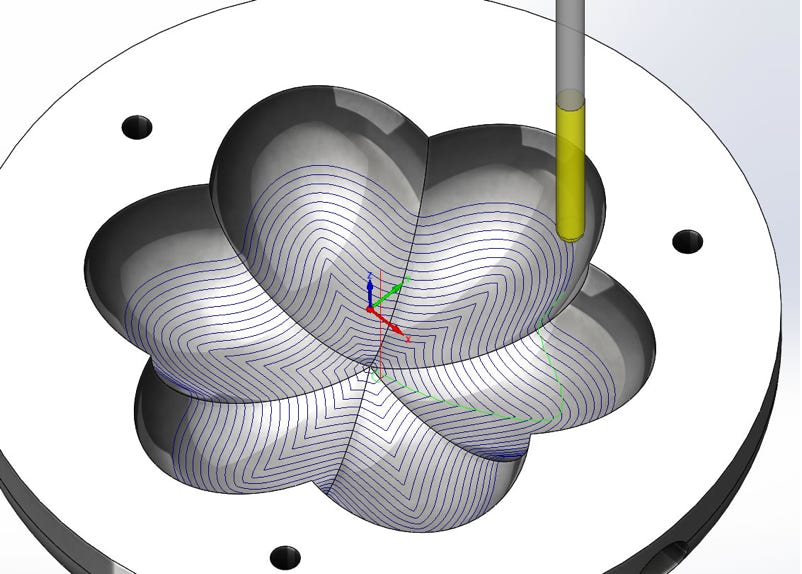

Spiral Machining

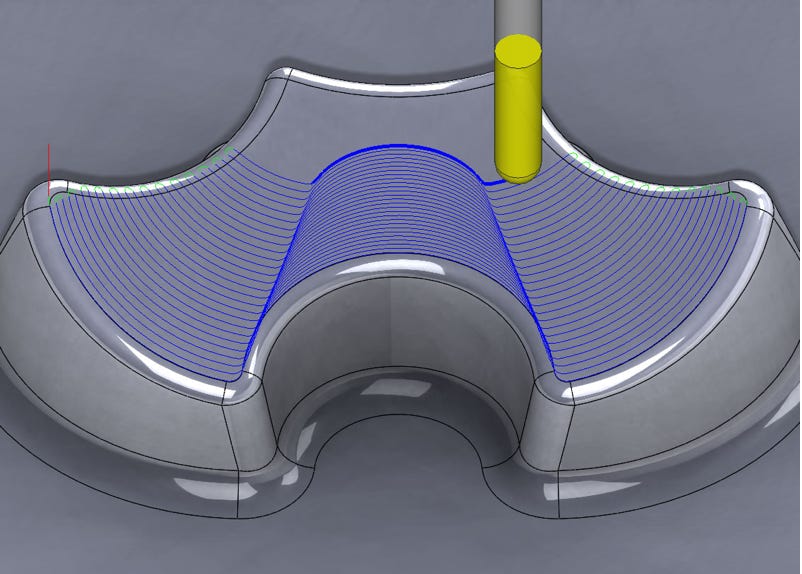

Morphed Machining

Offset Cutting

A spiral tool path radiating from a central point that keeps constant contact between the cutter and part, as it machines within a given boundary

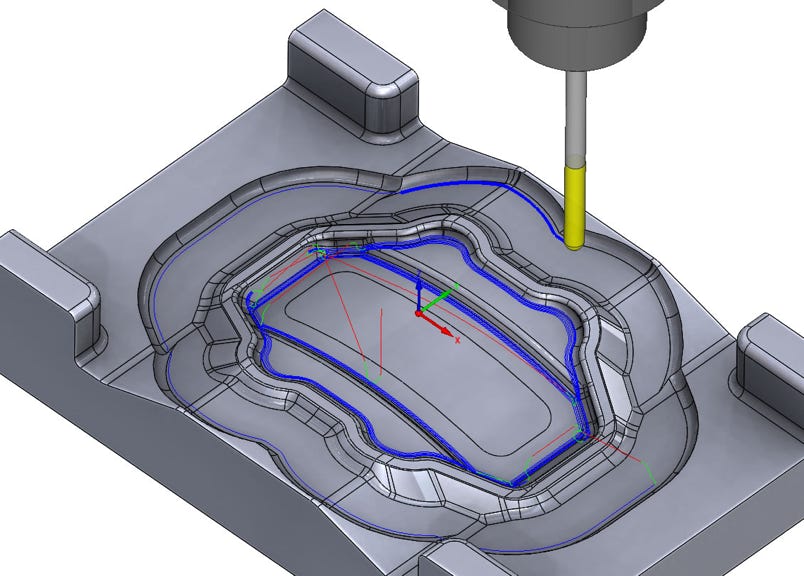

Boundary Machining

Morphed machining strategy cuts the surface with passes that resemble the shape and direction of the drive curves. Each path gradually changes its shape to transform from the first defined curve to the second one.

Rest Machining

3D Constant Stepover

The parallel to Drive curve cuts are multiplied and offset by user-defined step over, to machine the part surface.

Produces a single path along a defined Drive boundary - popular for Engraving and Chamfering.

Determines remaining material left by previous operations, and generates a tool path that only includes the left over stock.

Equidistant 3D passes along the surface of a part give full model coverage, providing high surface quality.

Pencil Machining

Parallel Pencil Milling

3D Corner Offset

Creates tool paths along internal corners and extremely small fillets to remove material that no other strategy can reach. Ideal for finishing corners and areas where the surface radius is the same as the cutter.

An extension to Pencil milling where the user multiplies single line tool paths by using defined Step overs. Particularly useful when the previous cutting tool was unable to machine all internal corners to size.

A set of equidistant pencil passes, created at the corners of the part, follows the 3D surface of a model to provide smooth finishing.

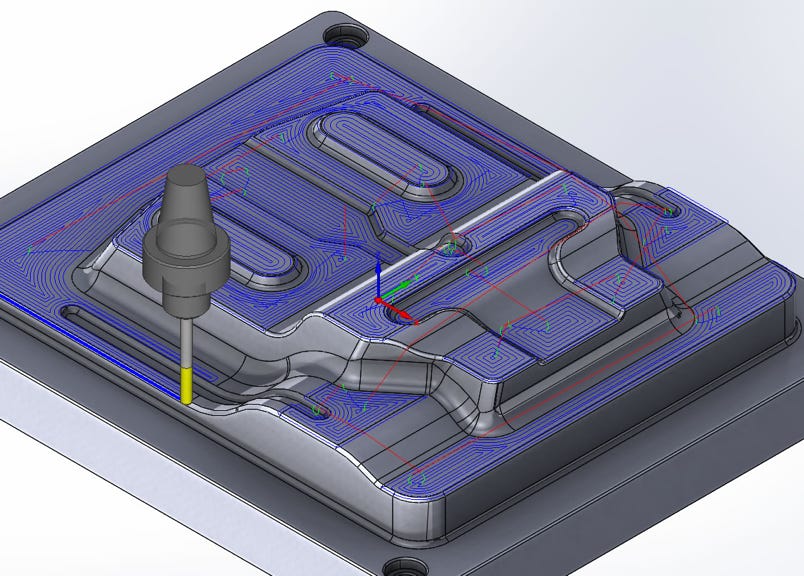

Prismatic Part Machining

Designed specifically for finishing parts containing features located on flat planes, including shallow faces and vertical walls.

Combined Strategies

Combines a Constant Z machining tool path with the following tool path strategies:

• Horizontal Machining

• Linear Machining

• 3D Constant Step Over

• 3D Corner Offset Machining

The SolidCAM Brochure

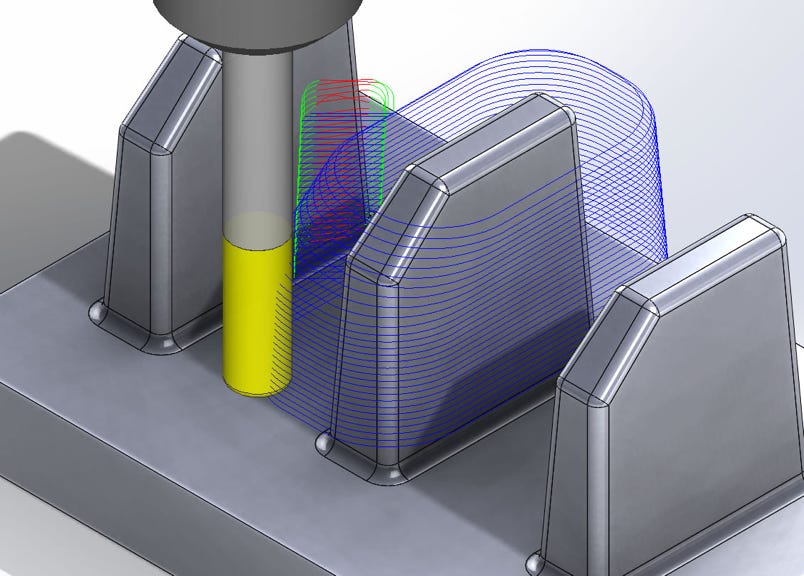

Indexial Multi-Sided Machining

A common scene in any machine shop today is that 4- and 5-axis CNC machines are increasing production, providing faster cycle times.

SolidCAM provides an effective and easy way to program on multiple sides of a part. SolidCAM is exceptionally strong in indexial 4/5-axis machining.

Easiest Coordinate System Definition for Indexial 5-Axes!

Tired of dealing with construction views, copying models, and rotating them in space for new alignments? Do you still copy and transform geometry to separate layers for indexial programming?

Experience single machine home position, with One-click orientations for indexed setups – SolidCAM speeds up multi-sided machining by eliminating multiple coordinate system constructions. Define a Coordinate System on the fly, by just picking a face, and continue programming your part.

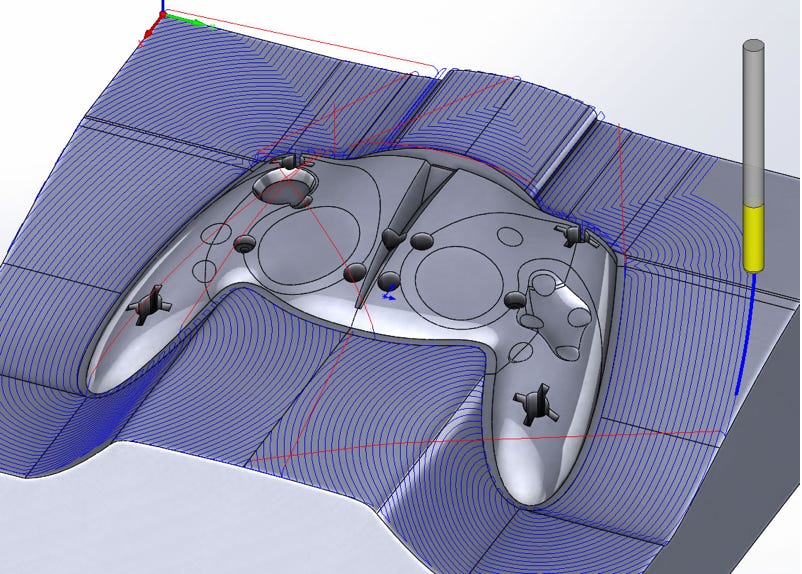

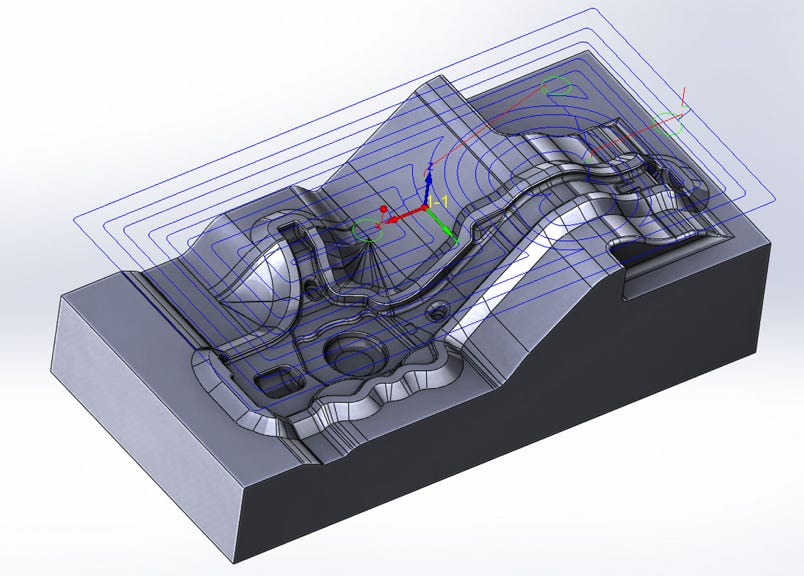

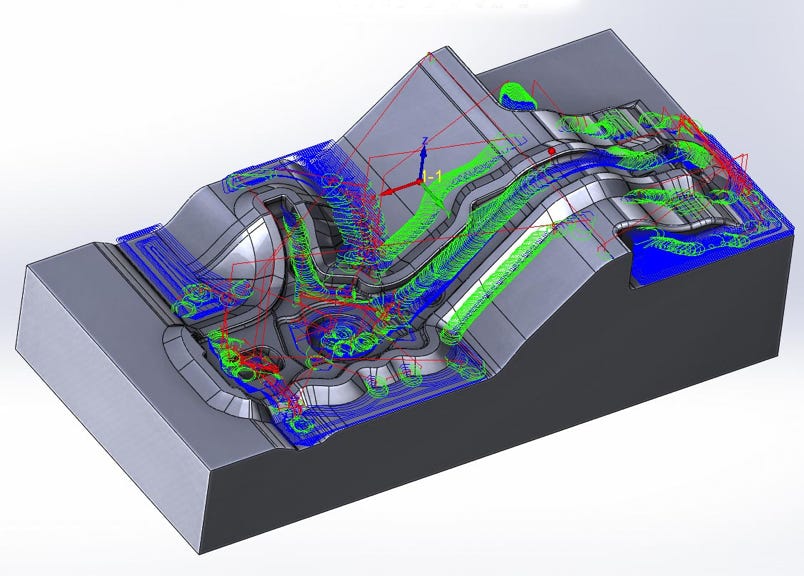

HSR Roughing

Contour Roughing

Hatch Roughing

Rest Roughing

Pocket-style tool path for sections generated on different Z-levels, specified by a definedStep down.

Typically generates a straight line tool path on each level of cutting. Useful for the machining of soft materials and parts containing shallow areas.

Completes stock removal for areas missed by larger tools. Uses an updated stock model of the remaining material to avoid air-cutting.

Hibrid Rib Roughing

HM Roughing (Hybrid Machining)

For machining of thin walls with very exotic materials, including titanium, graphite, etc. Combines roughing and finishing tool paths to preserve the highest possible part rigidity.

The HM Roughing strategy reduces rapid movements by controlling the tool motion to remain on the part following previous cut paths, instead of rapid feeding to the new position. Additional tool path optimization features include the automatic machining of flat areas only, rather than adding extra Z-levels to clean up planar zones. This roughing strategy enables the use of a large step over (greater than 50%).

Efficient, Edit-Free G-Code for Multi-Axis Machines

SolidCAM offers multiple options to get efficient G-code for multi-axis machines.

SolidCAM‘s post processor can be set up to handle all rotations and work offset shifting, to eliminate the need for setting up multiple work offsets at the machine. Whether your controller can calculate part rotations internally or it needs the post processor to handle rotations, SolidCAM has this covered. For controllers with advanced plane rotation or coordinate rotation functions, SolidCAM’s post processors are built to use these internal CNC functions. If you have a machine without such functions, users can input the part location inside SolidCAM and the G-code will handle all of the transformations for each rotation.

Our philosophy to indexial milling is simple: from software to G-code – make the process for indexial milling the same as for single-sided milling. No need for any special functions or tricks inside the software to machine multi-sided parts – it should just work!

The Most Powerful & Easiest-to-Use Coordinate System Definition

Authorised value added Reseller SOLIDWORKS

About Us

HEXAGON

SOLIDCAM

SOLIDWORKS

3D EXPERIENCE

Contact Details

UG-11, Ansal Majestic Tower,

G-Block, Vikas Puri,

New Delhi. 110018

(INDIA)

+91 98109 06052

info@sks3d.com

Copyright - SKS Scantech Engg. Exim Pvt. Ltd.

Developed and Maintained by : Arc Designs